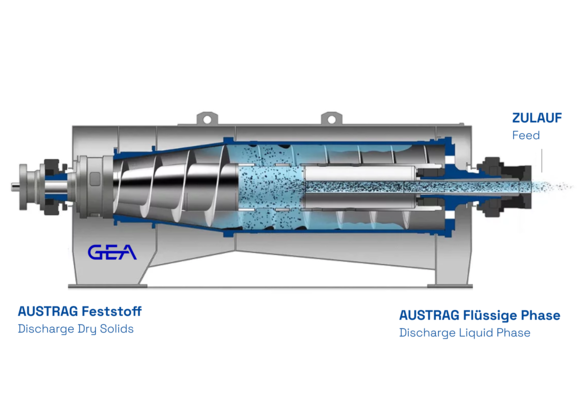

ATEX three-phase decanter

Maximum separation efficiency in just one step

Solids, oil and water are separated from each other in a closed circuit under a nitrogen atmosphere. The prerequisites for this are that the liquids are not soluble in each other, that they have different densities and that the solids are present as the specifically heaviest phase.

The solids are then disposed of, while the oil is returned to the production process for reprocessing. Minimizing waste while maximizing the use of raw materials makes the decanter an environmentally conscious "separation professional".

Your advantages

Increased safety

- Application-related wear protection

- Monitoring by sensors and evaluation systems

- Explosion protection in accordance with the ATEX directive

Increased efficiency

- Economical three-phase separation

- Highest possible purity of the phases to be separated due to adjustable peeling disk

- Individually manufactured decanter screws

Environmentally friendly

- Gas-tight system, which is overlaid with nitrogen; thus no fugitive emissions are produced

Our technologies at a glance

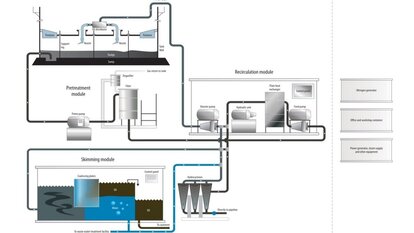

ATEX Blabo system

The Blabo system was specially developed for cleaning large-volume oil tanks and can be customized...

ATEX Manway Cannon

The Manway Cannon is a unit consisting of a cleaning nozzle, video cameras and spotlight and is fixed in a cleaning opening of the tank...

ATEX Robotic Dozer

The dozer was developed for use in ATEX zone 0 and can clean above-ground oil tanks and oil sludge pits in confined, potentially explosive spaces...