ATEX Blabo system (injector cleaning)

The All in One solution

The Blabosystem was specially developed for cleaning large-volume oil tanks and can be individually adapted. Tank cleaning can be carried out alone, or tank cleaning, sludge separation and oil recovery can be carried out in an integrated process. BLABO complies with the ATEX directive and is suitable for both floating and fixed roof tanks.

Your advantages

Increased safety

- No need to enter the tank

- Continuous monitoring and automatic shutdown functions

- No risk of explosion

- The system complies with the ATEX directive

Increased efficiency

- Integrated process of tank cleaning, sludge separation and oil recovery possible

- Up to 80 % time saving during tank cleaning (compared to manual cleaning)

- Shorter overall downtime of the tank

Environmentally friendly

- Closed cleaning process minimizes emissions

- Almost 100% recovery of hydrocarbons

- Reduced consumption of water, electricity and air

Cost savings

- Reduction of labor costs through automation

- Extended tank maintenance intervals

No man entry - efficiency and safety first and foremost

More efficient, faster and safer - outstanding advantages of this automated process compared to manual cleaning techniques, as no "man power" is required in the tank itself. The closed cleaning circuit enables almost 100% hydrocarbon recovery.

Good for your tank - good for the environment!

Our technologies at a glance

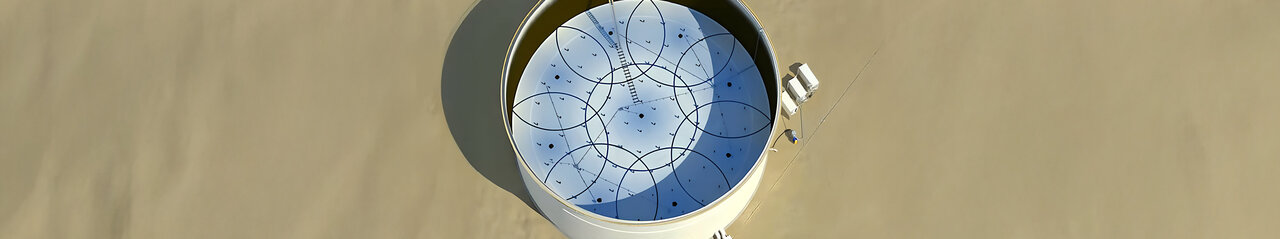

ATEX Manway Cannon

The Manway Cannon is a unit consisting of a cleaning nozzle, video cameras and spotlight and is fixed in a cleaning opening of the tank...

ATEX Robotic Dozer

The dozer was developed for use in ATEX zone 0 and can clean above-ground oil tanks and oil sludge pits in confined, potentially explosive spaces...

ATEX three-phase decanter

Three-phase decanters are manufactured exclusively in Germany to the highest quality standards. The separation process can be adjusted at any...